3–Way Valves

Specializing in standard and custom high pressure valves for

water hydraulics and other high pressure water systems.

water hydraulics and other high pressure water systems.

Valv–Trol 3–Way Diverter and

Selector Valves

Our versatile 3–way valves have been designed for directional control of most liquids from 150 PSI (10 bar), to over 10,000 PSI (690 bar). Although Valv–Trol offers some un–balanced 2–way and 3–way valves for lower pressures, most of our valves feature heavy duty balanced designs. This means that the internal forces are in balance, so shifting is smoother, and pressure can be applied to any port. You will not experience the sudden slamming common with other designs.

In addition to the 3–way diverter and selector valves, Valv–Trol also manufactures 2–way and 3–way valves for a wide variety of high pressure water, and fluid power applications. Sizes range from ½” to 4”, with both pneumatic and hydraulic actuators. Larger sizes to 10”, and higher pressures to 30,000 PSI

(2070 bar) are available on a custom basis

3,500 PSI (240 bar) Air

Actuated 3–way Diverter

6,000 PSI (415 bar) Hydraulic

Actuated 3–way Diverterr

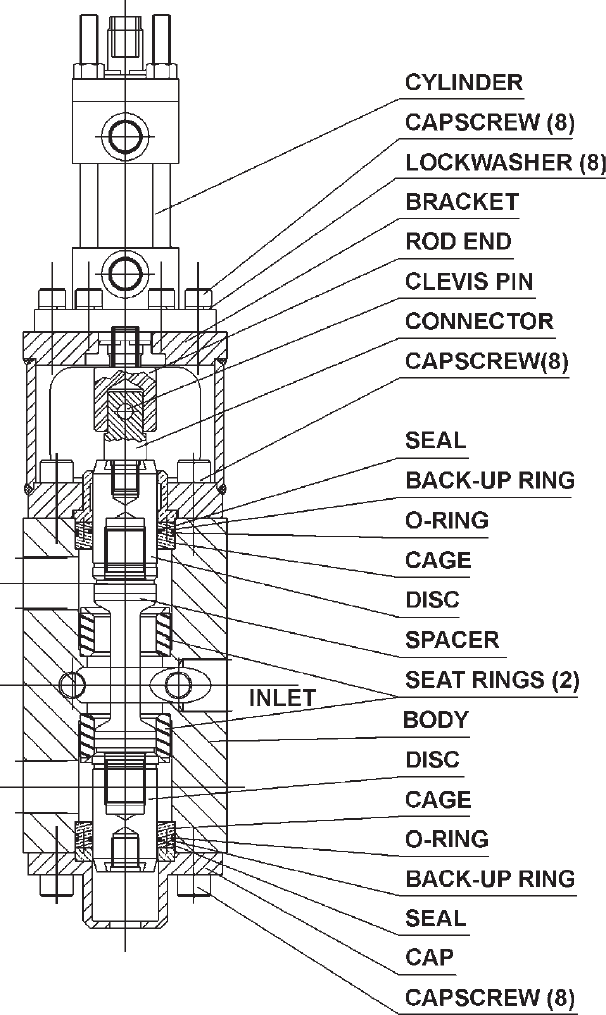

Cutaway of a typical diverter valve

3,500 PSI (240 bar) Air

Actuated 3–way Diverter

Valv–Trol 3–Way Diverter

Service

Diversion service generally means that one flow stream is directed to either of two outlets. A diverter valve has one inlet port, and two outlet ports. One outlet is normally open (NO), and the other is normally closed (NC). When the valve is shifted, the flow changes from one outlet to the other. A typical diversion circuit is shown below:

One common application is to shift the output of a positive displacement pump to a set of spray nozzles, or back to the reservoir. This could be for spray cleaning, machine tool cooling, or any number of high pressure applications. This saves the user money, by loading the pump only when high pressure is needed. Less load time = $$$ Savings!

Valv–Trol also protects your pump by making sure one port starts opening, before the second port goes closed. This helps prevent a dangerous pressure increase, known as “deadheading”, which can damage the pump, or needlessly pop a safety relief valve

Selector Service

Applications include shifting between two different pressures, two different fluids, or two different temperature liquids. Valves can be either open centered or closed centered, depending on your needs. Some valves can be modulated to mix a portion of both inputs.