Back Pressure Relief Valve

Specializing in standard and custom high pressure valves for

water hydraulics and other high pressure water systems.

water hydraulics and other high pressure water systems.

BACK PRESSURE RELIEF VALVES

FOR WATER, 95/5, OIL OR OTHER LIQUIDS PRESSURES

TO 25,000 PSI (1,724 Bar)

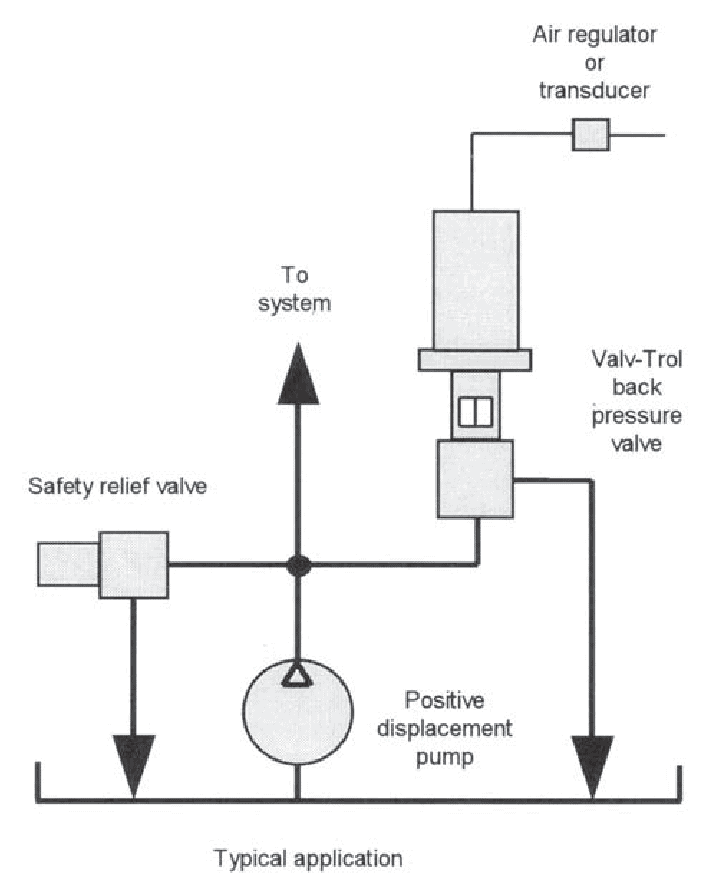

The Valv-Trol Back Pressure Relief Valve is sometimes called a Back Pressure Regulator or Bypass Valve. It is used to regulate the discharge

pressure of a positive displacement pump

The valve is mounted in a branch off the main discharge pipe, and acts as a

modulating relief valve. If pressure tries to rise above the set point, the valve

relieves only enough fluid to prevent a pressure rise. This is accomplished

without the full lift and excessive blowdown of a spring loaded relief. The valve comes complete with precision air regulator or pressure transducer and does

not require any outside controller or feedback loop.

Ideal for applications requiring pressure regulation with large or

frequent flow variations.

Wide range of optional features, such as body and trim materials,

port connections, flow rates, and pressure ratings.

Allows you to choose the best valve for your application.

Allows you to choose the best valve for your application.

The valve is simple in concept

.Requires no special tools for maintenance.

.Requires no special tools for maintenance.

Our valves are all subjected to 100% pressure

testing to ensure proper operation before

we ship to our customers.

BACK PRESSURE RELIEF VALVES

bulletin A-33

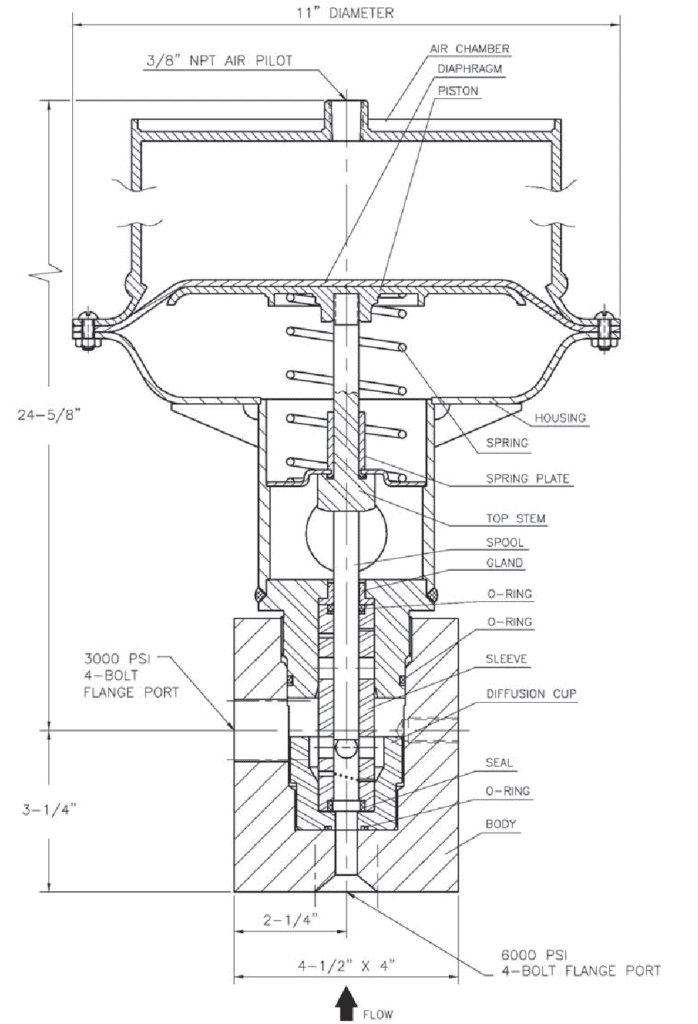

Illustration shows a typical valve. Please consult Valv-Trol for other features not shown.

BACK PRESSURE VALVES—PRINCIPLE OF OPERATION

The valve operates by balancing the liquid system pressure and a constant air pressure applied to the diaphragm

by the precision regulator. An internal spool is positioned to adjust the effective orifice size for proper flow

The pump is usually oversized slightly to allow some bypass flow through the valve under normal conditions. Once

the pump is running and a constant air pressure is applied, the spool finds its balancing point, and the pressure

stabilizes. The higher the air pressure, the higher the liquid system pressure

If system demand increases (more nozzles added, valves opened, etc.), the spool moves down to close off more

holes and prevents a pressure drop. If system demand decreases, the spool moves up to open more holes and

prevents a pressure rise..

THE VALV-TROL CO., STOW, OHIO